Our products

API 16A

Drill-Through Equipment

API Specification 16A covers Drill-Through Equipment for the oil and gas industry. This includes Drilling Spools, Adapter & Spacer Spools, Clamp Hub Connectors, and Blow Out Preventers. Academy is a long-standing API 16A Monogram license holder for Drill-Through equipment and stands behind our products. Our experience and successful track record help ensure that you will get a top-quality product, every time.

Academy Petroleum has fully equipped machining and welding facilities to service and repair and re-certify your used or damaged Drill-Through Equipment.

Over the years, Academy has developed an extensive library of field proven designs for a variety of Drill-Through Equipment to meet industry needs. We are also happy to work with you to develop new configurations based on your needs.

The latest addition to our 16A product scope is our Annular BOP. Academy is proud to offer our 7 1/16” – 5,000 Spherical style Annular BOP bearing the API Monogram as a testament to its unbeatable quality.

API 16C

Choke and Kill Equipment

API Specification 16C covers Choke and Kill Equipment for the oil and gas industry. Academy Petroleum’s Monogram scope includes Rigid Choke and Kill Lines and Buffer Chambers. API imposes stringent quality requirements for API 16C equipment to ensure the safety of the operating personnel. Academy is a long-standing API 16C Monogram license holder for Choke and Kill equipment. Our experience and successful track record help ensure that you will get a top-quality product, every time.

Over the years, Academy has developed many field proven designs for Choke and Kill Equipment. We are also happy to work with you to develop new configurations based on your needs.

Academy is proud to announce the addition of Buffer Chamber design and manufacture to our 16C product monogram scope.

API 6A

Wellhead and Christmas Tree Equipment

Academy Petroleum Industries is licensed by the American Petroleum Institute to Design, Manufacture, & Supply API 6A Monogrammed equipment. Being an API Monogram program licensee holds us to the highest standards of product quality and integrity. Ordering your API 6A equipment from Academy ensures that you will receive a top-quality product in a timely manner.

Our API 6A Monogram program scope includes Adapter and Spacer Spools, Casing and Tubing Heads & Hangers, Tubing Head Adapters, Tees, Crosses, Threaded Connectors, Flanged Connectors, Top Connectors, and Other End Connectors.

Academy Petroleum is also equipped with state-of-the-art weld overlay cladding machines and can provide Stainless Steel or Corrosion Resistant Alloy overlays on your wellhead equipment to withstand the harshest of environments. Our welding procedures are in full compliance with API requirements and relevant ASME specifications.

We are also able to work with our customers on custom equipment designed and manufactured to API Specification 6A.

HANGER FLANGE

These slim, easy to install units can be used anywhere in your Drilling or Completion/Workover BOP stack.

Academy Petroleum Industries Hanger Flange provides a safe means of hanging off a drill string or tubing where it is impractical to land the tubing hanger. This allows the tubular to be hung off at any point during the operation, no matter if the tubular is in the light or heavy position. These slim, easy to install units are readily adaptable and can be installed anywhere in your Drilling or Completion/Workover BOP stack.

The Hanger Flange is typically installed above or below the Annular or Rotating BOP between the stripline. It is manually activated by rotating the lag bolts. These units are especially useful when changing stripping elements while under balanced drilling. It is also useful when stripping on or off a snubbing unit while drilling, allowing the drilling rig to strip the drill string until the balanse point, before rigging in snubbing equipment.

- Low profile, compact design

- Three sizes available: 7 1/16" 5,000 PSI, 11" 3,000 PSI & 13 5/8" 5,000 PSI

- U-cup seal design enables simple, quick engagement of hanger dies - no need to adjust gland nuts as with a packing type seal

- Academy Petroleum offers an optional inlay of Ring Grooves with Stainless Steel or Inconel

- Each unit comes with MTR's, Letter of Compliance and Pressure Test Certificates

- Academy's Hanger Flange can work for any application where weight of tubular strings needs to hang-off for any reason

- Academy Petroleum's Hanger Flange is by far the most superior hanger flange on the market

- Academy Petroleum also manufactures and sells various snubbing grippers and Blow-out Preventors for use on the snubbing rig

ACADEMY TYPE RS-100 TUBING STRIPPER

Academy Type RS-100 Tubing Stripper provides a safe and economical means for stripping long strings of tubing or drill pipe in or out of the well under pressure. The body and cap of the RS-100 are fabricated from high-strength steel for long, trouble-free service and economical operation and maintenance.

The RS-100 Tubing Stripper can be used in combination with an Annual Blowout Preventor for stripping long strings of tubing or drilling pipe under pressure. In this configuration, the annual BOP is operated only to seal off the wellbore in the event of emergency, or when passing oversized joints and hangers. By using the combination of an annular BOP and a stripper head, the point of seal can be transferred either above or below the oversized component. This eliminates the need to strip these through a closed unit.

The RS-100 Tubing Stripper comes with a 7 1/16 - 3000 or a 7 1/16 - 5000 bottom connector flange, with a maximum working pressure of 3000 PSI. They are hydrotested to 4500 PSI.

Physical Data

| Bottom connector API flange | 7 1/16 - 3000 | 7 1/16 - 5000 |

|---|---|---|

| Height | 21 3/4” | 23 1/2” |

| Diameter | 14” | 14 1/2” |

| Bore Through Body | 7 1/16” | 7 1/16” |

| Bore Through Cap | 6 3/8” | 6 3/8” |

| Max. Working Pressure Rating | 3000 PSI | 3000 PSI |

Parts List

| Item | Part No. | Description | Qty |

|---|---|---|---|

| 1 | TS-7.06-xxx-RS-100 | Body of Stripping Head, 7 1/16” 3000/5000, Type ‘RS-100’ | 1 |

| 2 | TS-SEAL-RS | Cap Seal, Buna, RS-100 | 1 |

| 3 | RS-7.06-xxx-CAP | Stripper Cap Head, 7 1/6” 3000/5000 Type ‘RS-100’ | 1 |

Note: Rubber elements, slip bowl and slips are not supplied.

ROTATING FLANGE SPOOLS

Our rotating spools and flanges can be found on wellheads and service equipment throughout North America.

Academy Petroleum Industries can improve your company’s productivity and bottom line by offering API 6A and API 16A rotating flange spools for oil and gas wellhead applications. The incorporation of a lap joint flange into an API RT J type end connection facilitates easy bolt up and allows outlets to be positioned in any orientation. Academy can also retrofit existing wellhead equipment such as BOPs with a rotating flange for increased versatility.

Academy is a licensed manufacturer of a complete line of engineered API 6A and 16A rotating spools, with or without outlets, in nominal sizes from 2 1/6” through 13 5/8” and working pressures from 2,000 PSI through 15,000 PSI.

Academy rotating spools and flanges are manufactured in our 96,000 square feet machining and welding facility in Edmonton, Alberta, Canada. By performing all fabrication, inspection, and test procedures in house, we are able to maintain consistently high product quality.

ACADEMY RAM TYPE QRC BOP

Designed to withstand the rigors and harsh environments of the Canadian oilfield.

The Academy Type BOPs are used in well workover, snubbing and coil tubing drilling operations. Originally designed to withstand the rigors and harsh environment of the Canadian oilfield, these rugged, reliable ram BOPs are now in service from China and Australia to the frozen Arctic.

Features

- Lightweight and easy to install

- Simple parts replacement

- Quick ram changes accomplished with only a small hammer

- Economical, yet designed to the highest standards for endurance and reliability

- Available in a variety of end connections and pressure ratings

- Visual indication of ram position at all times

- Simple, reliable manual lockout shafts provide secure lockout capability and visual indication of status

- Complies with Nace and API requirements for H2S service

- Optional internal bleed-off and equalize valves above and below rams available without adding any overall height

- Full 7 1/16 opening

- Full array of blind, pipe, offset pipe, and slip rams available for all sizes

- Rotating bottom end connection with API 6A monograms are available

- All seals are proven lip type designed with longer life and maximum reliability

Dimensions And Weights

| Item | Flange X Flange | Stud X Stud | Stud X Flange |

|---|---|---|---|

| Approximate Weight | 1,980 lbs (898 kg) | ||

| Overall Height (no studs)* | 25” (635 mm) | ||

| Overall Length | 76” (1856 mm) | 76” (1856 mm) | 76” (1856 mm) |

| Overall Width | 34” (830 mm) | 34” (830 mm) | 34” (830 mm) |

| Working Pressures** | 5000 PSI (34.5 MPa) | 5000 PSI (34.5 MPa) | 5000 PSI (34.5 MPa) |

* Add 1” to overall height when a bottom rotating flange is used

** Working pressure may be 3000 PSI (20.7 MPa) depending on end connection

SNUBBING SLIPS

Academy Petroleum’s Snubbing Slips (also known as Snubbing Grippers) are used on a snubbing rig to securely hold the pipe being run in to or pulled out of the well. They feature a double acting hydraulic cylinder which will grip and release the pipe automatically when the control valve is operated by the snubber. Differing styles of slips are used to support either the weight of the pipe or the pressure load trying to push the pipe out of the hole. As well, some types of slips need to move with the pipe (travel) and some hold the pipe stationary while the traveling slips are repositioning on the string.

Academy Petroleum Industries manufactures several different types of Snubbing Slips to fulfill these various roles. These Snubbing Slips are used throughout Alberta, the Middle East and around the word.

Travelling Heavies

The Travelling Heavy version of the slips is pictured at right. They are intended to support the weight of the pipe and are mounted on the travelling plate of the snubbing rig so that they move up and down with the pipe. As they are the uppermost slip on the snubbing rig, and no additional equipment is mounted above them, Travelling Heavies are only supplied with a bottom flange to mate with the travelling plate and no upper flange.

Snubbers/Stationary Heavies

The Academy Snubber Slips are typically used in three configurations: a Stationary Snubber, a Traveling Snubber and a Stationary Heavy. The picture shows these slips in the stationary heavy configuration. There is a 7” bottom flange for mounting the slips directly to the top of the BOP stack, and a custom sized top flange for bolting on the stationary snubber. When used as a snubber (either stationary or traveling) these slips are inverted. For example, the traveling snubber would have the 7” flange on top for bolting to the traveling plate.

Dual Stationaries

The Dual Stationary version is used on snubbing rigs in order to minimize stackup height and weight. It combines both the Stationary Heavy and Stationary Snubber into the single unit. As can be seen in the equipment specifications table, this saves 6 1/2” of stackup height and 100lbs of weight.

Equipment Specifications

| Weight (W/O Carriers) / Overall Height | |

|---|---|

| Nominal Size* | 7” (7.06” Full Bore)* |

| Available Tubing Sizes | 1.315” to 5.5” |

| Load Rating | 200,000 lbs |

| Slip Type | Cavins® Model ‘C’ Carier & Dies |

| Hydraulic Pressure | 1500 PSI (Rated) 750 PSI (Operating) |

| Hydraulic Connections | 1/2” NPT |

| Travelling Heavies | 10.0” |

| Snubbers/Stationary Heavies | 16.6” |

| Dual Stationaries | 26.6” |

| Travelling Heavies | 220 lbs |

| Snubbers/Stationary Heavies | 370 lbs |

| Dual Stationaries | 650 lbs |

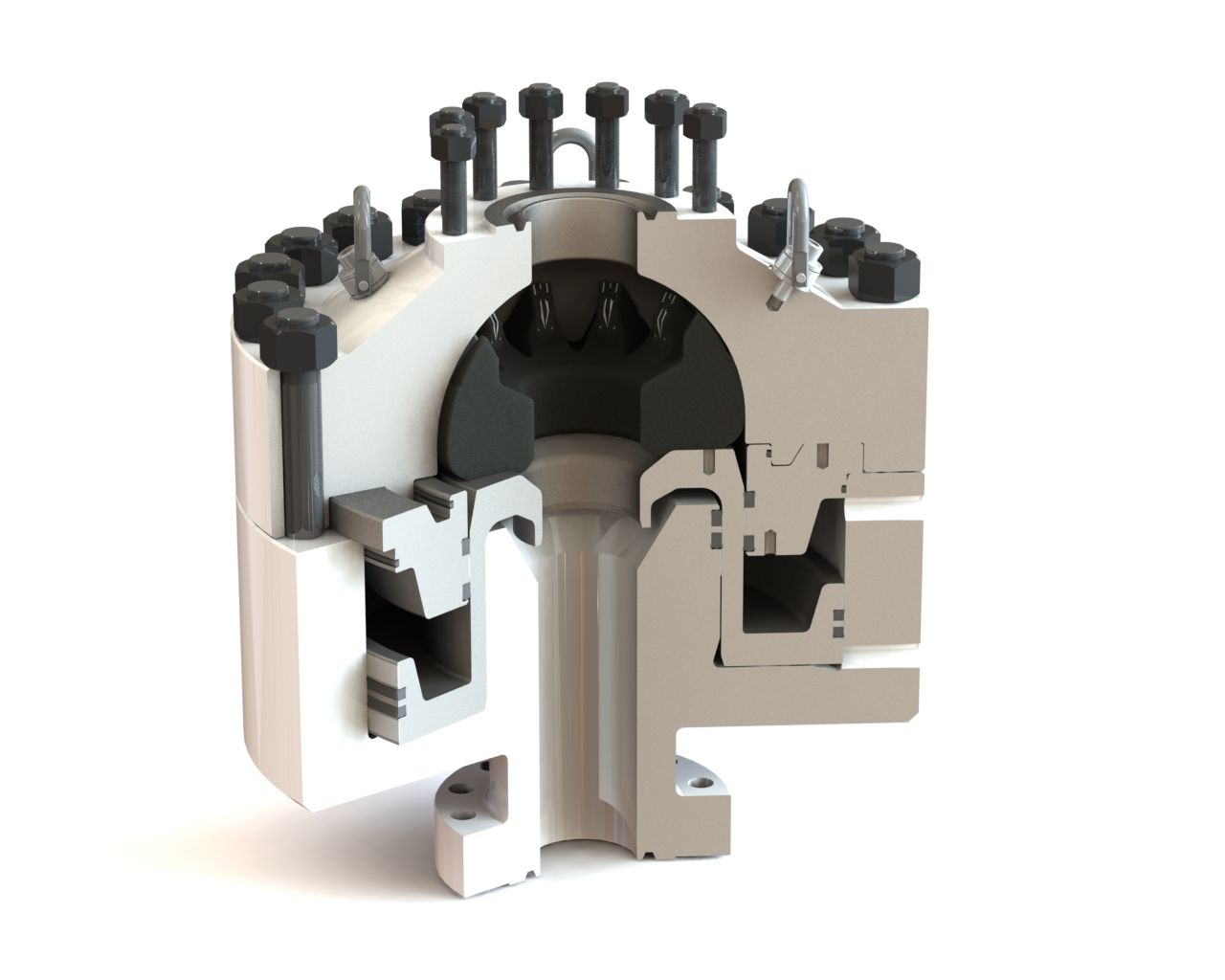

ACADEMY - 7 1/16'' 5,000 TYPE 'S' API 16A MONOGRAMMED SPHERICAL BOP

Academy Spherical Blowout Preventors are a compact annular BOP designed to seal reliably on almost any size or shape of object in the wellbore (ex: drill pipe, kellys, casing and wirelines). They can also be used to maintain pressure control while stripping pipe into and out of the hole and they incorporate specific design features to suit snubbing applications. Academy BOPs were originally designed to withstand the rigors and harsh environment of the Canadian oilfield, but these rugged, reliable BOPs are now in service from China and Australia to the frozen Arctic.

Features

- Designed and monogrammed as per API 16A specification

- Simple, reliable design & construction:

- Only five major components

- Only two connections needed for Hydraulic System

- Wear rings are supplied on moving parts to maximize the life of steel components and seals

- Seal element can be changed without contaminating the hydraulic system

- Manufactured from high quality steel forgings

- Compact design, lower overall height than most other BOPs

- Rated for Sour H2S Service as defined by API 15A & NACE MR-0175

- Suitable for low temperature applications

- Full opening bore

Design Principle

When hydraulic fluid is pumped into the closing port it fills the closing chamber below the piston, causing the piston to rise. The rising piston pushes on the seal element which then rides upwards and inwards on the spherical profile of the lid. As the sealing element is squeezed into the well bore, it will contact and seal on any size or shape of object in the well bore. If there is no object in the bore, the sealing element will continue to squeeze shut until it seals of the entire bore.

Operating Characteristics (7 1/16 - 5000 Model Only)

Spherical BOP Parts List

| Item | Description | Qty |

|---|---|---|

| 1 | Lower Housing | 1 |

| 2 | Upper Housing (lid) | 1 |

| 3 | Piston | 1 |

| 4 | Adapter Ring | 1 |

| 5 | Element (Supplied Separately) | 1 |

| 6 | Retainer Tab | 2 |

| 7 | Capscrew | 2 |

| 8 | Stud (for Bolted Cover) | 24 |

| 9 | Nut (for Bolted Cover) | 24 |

| 10 | Stud (for Flanged Connection) | 12 |

| 11 | Nut (for Flanged Connection) | 12 |

| 12 | O-Ring, Adapter Ring (Inner) | 1 |

| 13 | O-Ring, Adapter Ring (Outer) | 1 |

| 14 | Hydraulic Seal, Adapter Ring (Upper) | 1 |

| 15 | Hydraulic Seal, Adapter Ring (Lower) | 1 |

| 16 | Hydraulic Seal, Lower Housing (Upper) | 1 |

| 17 | Hydraulic Seal, Lower Housing (Lower) | 2 |

| 18 | Hydraulic Seal, Piston | 2 |

| 19 | Wear Band, Piston | 1 |

| 20 | Wear Band, Lower Housing | 1 |

| 21 | Wear Band, Adapter Ring | 1 |

ACADEMY - 5 1/8" 10,000 SPHERICAL ANNULAR BOP

Academy Petroleum is proud to offer the first 5 1/8" - 10,000 Spherical BOP to market. This BOP was developed to fill a gap in the market and avoid the need to use a larger BOP with a crossover spool. Academy’s Spherical Blowout Preventer is a compact annular BOP designed to seal reliably on virtually any size or shape of object in the wellbore and is capable of Complete Shut Off (CSO) at rated working pressure. It can also be used to maintain pressure control while stripping pipe in or out of the hole and is well suited for Coiled Tubing and Snubbing applications. Academy BOP’s are rugged, reliable and are proven performers in some of the toughest oilfield environments on the planet.

Features

- First 5 1/8" - 10,000 Spherical BOP on the market

- Designed, Manufactured and Tested in accordance with API Specification 16A

- Simple, reliable design and construction

- Only five major components

- Only two connections needed for Hydraulic System

- Wear rings are supplied on moving parts to maximize the life of steel components and seals

- Seal element can be changed without contaminating the hydraulic system

- Manufactured from high quality steel forgings

- Compact design, low overall height

- Rated for Sour H2S Service as defined by API16A & NACE MR-0175

- Suitable for low temperature applications

- Full opening 5 1/8" bore

Principal of Operation

Hydraulic fluid is pumped into the closing port, filling the closing chamber below the piston, moving the piston upwards. The piston forces the seal element upwards and is guided inwards by the spherical profile of the upper housing. As the sealing element is squeezed toward the well bore, it contacts the tubular and seals off the annular area. Due to the flexible design of the seal element, it will seal on virtually any size or shape of object in the well bore. If there is no object in the bore, the sealing element will continue to squeeze closed until it seals off the entire bore.

Our Brochures

Specifications

| Physical Data for Academy 5 1/8” - 10,000 Spherical Blowout Preventer |

|---|

| Rated Working Pressure (Well Bore) | 10,000 PSI (69.0 MPa) | Overall Height (Excl. Flange Studs) | 31.93 inches (811 mm) |

| Hydraulic System Rated Working Pressure | 1,500 psi (10.3 MPa) | Maximum Outside Diameter | 31.75 inches (806 mm) |

| Hydraulic System Recommended Operating Pressure | 1,500 psi (10.3 MPa) | Weight (Dry, Incl. Sealing Element) | 4,320 lbs (1,960 kg) |

| Hydraulic Closing Volume | 5.8 gal (US) (21.9 L) | Hydraulic Opening Volume | 5.0 gal (US) (19.0 L) |

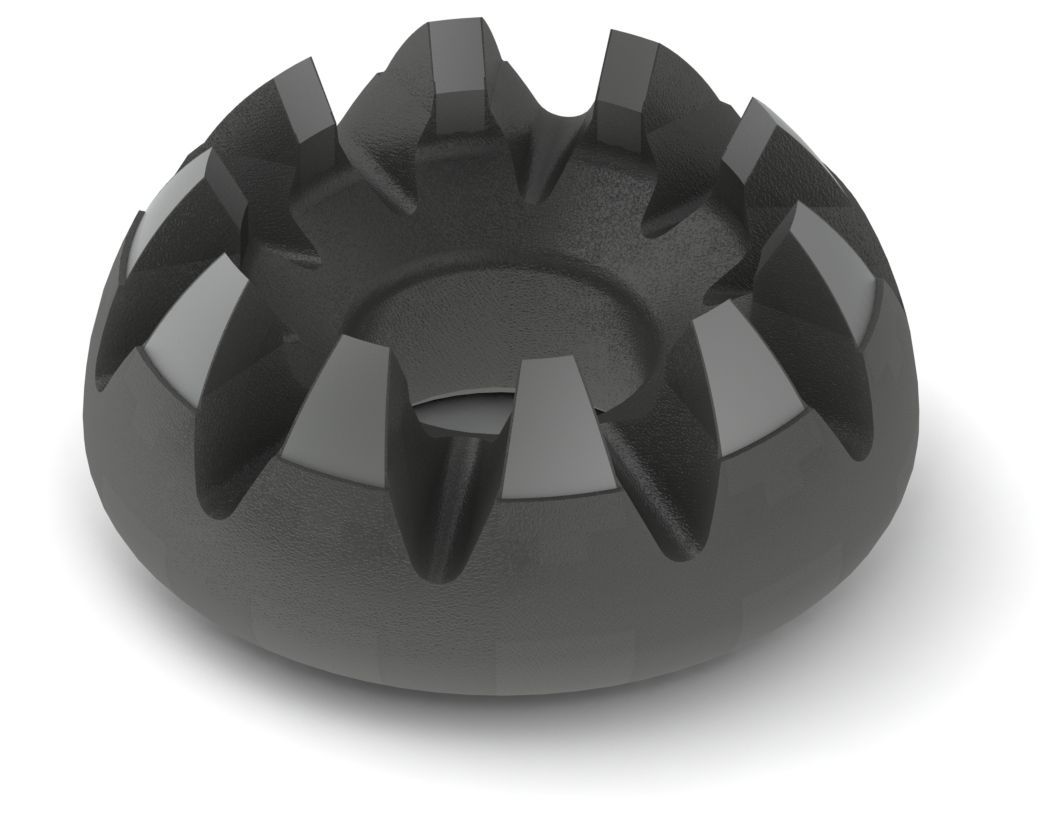

Annular BOP Packing Element

Academy Petroleum Industries 5 1/8" - 10,000 Annular BOP Packing Element has been designed to our specifications to ensure proper fitment and operation with our 5 1/8" - 10,000 Annular Blow Out Preventer. Our Packing Element is based on a time tested and field proven design used successfully in the oilfield for many decades. The Packing Element is designed, manufactured & tested in accordance with the stringent requirements set forth in API Specification 16A.

Academy Petroleum has specified superior materials for use in its construction, resulting in reliable sealing performance under a wide range of operating conditions. The steel reinforcing inserts are made from high quality low alloy steel that meets the requirements of NACE MR0175 for sour service applications. The elastomeric compound used in this Packing Element is Hydrogenated Nitrile Butadiene Rubber (HNBR), also known as Highly Saturated Nitrile (HSN). HNBR is used widely in the oil & gas industry particularly where Hydrogen Sulfide (H2S) gas is present due to its ability to withstand a wide variety of oils, fuels, and other chemicals. HNBR exhibits good weathering resistance and excellent mechanical properties in terms of tensile strength, tear modulus, elongation at break and abrasion resistance.

Our Packing Element design has been tested rigorously in accordance with API Specification 16A to ensure proper functionality and reliable sealing performance. In addition, each Packing Element is thoroughly inspected and fully function tested in accordance with API Specification 16A prior to leaving our facility.

| Physical Data for Academy 5 1/8” - 10,000 Spherical Blowout Preventer |

|---|

| Rated Working Pressure (Well Bore) | 10,000 PSI (69.0 MPa) |

| Maximum Outside Diameter | 15.03 in (382 mm) |

| Minimum Inside Diameter | 5.44 in (138 mm) |

| Overall Height | 6.82 in (173 mm) |

| Weight | 65 lbs (30 kg) |

| Temperature Rating | 0°F to 250°F (-18°C to 121°C) |

| Rated for H2S Service as Defined by API 16A & NACE MR0175 |

|---|

5 1/8” - 10,000 Spherical Blowout Preventer Parts List

| Item | Description | Qty |

|---|---|---|

| 1 | Lower Housing | 1 |

| 2 | Piston | 1 |

| 3 | Adapter Ring | 1 |

| 4 | Upper Housing | 1 |

| 5 | Packing Element | 1 |

| 6 | Housing Closure Studs | 20 |

| 7 | Housing Closure Hex Nuts | 20 |

| 8 | Seal, Adapter Ring | 2 |

| 9 | Seal, Lower Housing | 2 |

| 10 | Seal, Piston | 2 |

| 11 | Flange Studs | 12 |

| 12 | Flange Hex Nuts | 12 |

| 13 | Wear Strip, Lower Housing | 1 |

| 14 | Wear Strip, Piston | 2 |

| 15 | Wear Strip, Adapter Ring | 1 |

| 16 | O-Ring, Adapter Ring (Outer) | 1 |

| 17 | O-Ring, Adapter Ring (Inner) | 1 |

ACADEMY’S TRANSITION WELD-NECK FLANGES

Academy’s Transition Weld-Neck Flanges are manufactured with 100% Canadian premium steel forgings at our facility in Edmonton, Alberta, Canada.

Academy Petroleum’s Transition Weld-Neck Flanges are designed and manufactured at our facility in Edmonton, Alberta in accordance with API Specification 6A, ASME B31.3 & CSA B51. Flanges are machined from Canadian steel forgings with a 75ksi minimum yield strength in accordance with API 6A. Transition sleeves are machined from A350-LF2 Cl. 1 and welded to the flanges using an approved ASME IX welding procedure. Flange assemblies are then stress-relieved in calibrated furnaces to ensure a premium quality product. Using an Academy transition flange allows for a simple P-1 to P-1 field weld when transitioning from API wellhead equipment to ASME piping.

Academy holds a Certification of Authorization Permit with ABSA and has attained a blanket CRN (Canadian Registration Number) for our transition flanges.

CRN: 0B21121.2

Transition Flanges are available in various sizes for 10,000 & 15,000 API 6A connections

Academy Petroleum Hydrotest Press

Academy has designed and built several hydrotest presses to assist our customers with testing wellhead equipment and valves safely and efficiently. Using Academy’s test press provides our clients significant time savings by not having to bolt and un-bolt test flanges to the test equipment. The press uses interchangeable test plates to suit testing a wide range of sizes and pressure ratings. It may be configured horizontally or vertically depending on the needs of the client and the types of equipment to be tested.

Please contact Academy for more details and technical specifications for past builds. Academy is also happy to work with your company to develop a hydrotest press to suit your specific needs!

| Typical Specifications |

|---|

| Maximum Press Force: | 1,000 Tons (2,000,000 lbf) |

| Footprint Dimensions: | 53 ¼” x 53 ¼” |

| Overall Height: | 5.44 in (138 mm) |

| Overall Height | 114” (Or as required) |

| Weight (Dry, Exl. Pump & Accessories): | 15,500 lbs |

| Cylinder Stroke: | 17” |

| Hydraulic System Pressure: | 10,000 psi Max |