About Us

Our Quality Policy

Academy Petroleum Industries is committed to maintaining objectives, performance standards and continuous improvement of process and operations to ensure the supply of premium products to our customer expectations and maintain compliance to regulatory requirements.

Our Capabilities

Incorporated in 1985, Academy Petroleum Industries has grown to be a well-respected manufacturing, repair and fabrication facility in the global marketplace. With 100,000 sq. ft. in multiple sites, we are fully equipped to complete projects of all sizes.

Providing versatility in design, manufacturing, repair and service, our plant is well equipped with:

- Craneage ranging from ½ ton to 15 ton

- Versatile N.C.’s from 6” to 48” swing

- Manual Lathes from 12” to 36” swing

- Vertical Lathes up to 75” swing

- State-of-the-art welding equipment

- Hot Wire Tig Bore Cladding System

- Drilling Equipment

- Stress relief furnace

- Hydro Testing

- CNC Milling Machines

- Phosphating

- Sandblasting

- Peening

- Painting

As a one-stop-shop, we provide our customers with cost-effective and timely results. We have worked with many clients on specialty projects with great satisfaction. We strive to meet and exceed our customers requirements.

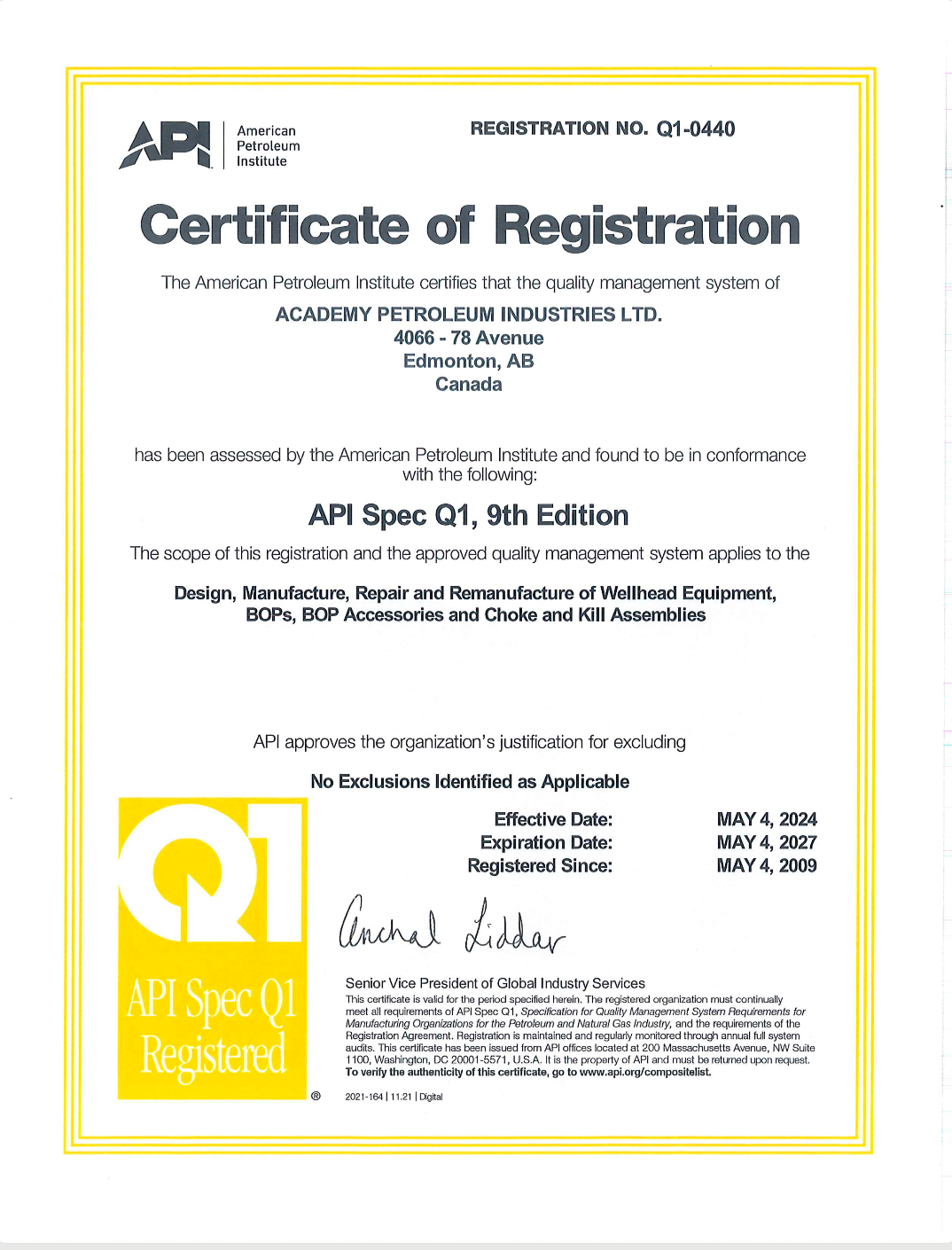

Academy Petroleum is licensed to The American Petroleum Institute API, International Standards Organization ISO, and Alberta Boilersbranch Standards ABSA.

We are dedicated to searching and implementing the best technologies available. With our in-house engineering, we develop new technologies and strive for continuous improvement of existing products.

Our Products

- Tubing Head Adaptors

- Studded Tees

- Studded Crosses

- Drill Through Equipment

- Flanges

- Weld Necks, Blinds, & Companions

- Drilling Spools

- Rotating Drilling Spools

- Snubbing Slips

- QRC Blowout Preventors

- Ram Blocks

- Spherical BOPs

ENGINEERING AND DESIGN

We have extensive

in house engineering and

design capabilities, prototype and validation testing.

Academy Petroleum Industries has extensive in house engineering and design capabilities. With over 40 years of experience in the design of products for the oil & gas industry Academy can assist you in taking your product from concept to reality. Academy Petroleum is ISO 9001 & API A1 registered for design.

Our engineering staff utilizes cutting edge SolidWorks® 3D CAD software to help our clients visualize and realize product design. We also have the ability to create and edit 2D drawings through the use of DraftSight® software. Academy's engineering staff has formal training in the use of SolidWorks Simulation Finite Element Analysis software and have used it to verify and optimize many designs over the years.

Once a product is designed and manufactured, Academy can also assist you with prototype testing and design validation using our in house Pressure Test Facilities combined with our state of the art Quality Control and Measurement Capabilities. All equipment is fully calibrated and certified as per ISO requirements.

WELDING SHOP

Academy Petroleum Industries has extensive welding capabilities in order to meet our customer needs.

Our welding department consists of Grade B Pressure certified Journeyman Welders. We can weld almost any material thanks to our catalogue of over 60 welding procedures. We are also capable of welding using almost any process, such as SMAW (Stick/MIG), GTAW (TIG), SAW (Sub-Arc), and FCAW (Flux Core).

Our welding department include state of the art Hot-Wire TIG Welding systems which are capable of cladding bores and ring grooves with Inconels & Stainless Steels with amazing quality and disposition rates. To improve customer deliveries, Academy uses three furnaces to provide in-house Post Weld Heat Treatment services.

ARC-05HVTe Horizontal, Vertical, and Tilt Cladding System

With 6500lb capacity, the ARC-05HVTe is an automated system that has the capability to weld in the horizontal and vertical position, or and any angle between the 0 and 90 degree positions on the ID and OD of cylindrical parts. The ability to position part improves bead shape, weld chemistry and improves overall ease of operation and usability of welding process at high deposition. Two more hot wire T.I.G. machines with load capacities of 15,00lbs 70” of vertical welding height and 70” diameter.

Stress Relieve Furnaces

Our largest oven has a operational size of 122" long X 69" wide and 53" high. Smaller pipes can be feed through an access door making almost any length doable. Our two smaller ovens can both handle a maximum load size of 66"long X 66" wide X 53" high.

Academy Petroleum's QRC body

One of Academy Petroleum's QRC bodies being preheated in preperation of welding the 7" 5K flanges on.

Coil tubing BOP body repair

A customer supplied coil tubing BOP body has been sent in to have the ram bores reworked. A complete weld and re-machine of the bores

Safety

Academy Petroleum Industries is commited to providing a safe work environment for its workers, subcontractors, visitors, and the public at large.

Our objective is a Health and Safety Program that will reduce the number of injuries to an absolute minimum, not merely in keeping with, but surpassing the industry averages. Our goal is zero incidents and injures.

Part of this commitment includes the identification and control of physical and chemical hazards faced on the job. It also involves providing an inclusive work environment in which all are free from violence, harassment and discrimination, and all of the associated psychological hazards.

Academy Petroleum is proud to participate in the COR audit program and has been in good standing with its certifying partner the ACSA for over 23 years.

We are also committed to the process of continual improvement. This includes following industry trends and implementing new technology and processes tom make our worksites safer. We currently have AED’s and Emergency medical oxygen units at both of our sites. In addition to this we now exclusively utilize silica free abrasives for blasting operations.

Quality Assurance

Quality is our product

Quality Control team is certified to perform in-house surface NDE, Dimensional inspection, Visual inspection, Welding Inspection, Hardness testing in accordance with API 6A, 16A, and 16C specifications. These in-house activities have reduced our down time for product delivery.

The Quality Department at Academy consists of Quality Control and Quality Assurance which were instituted early on in Academy's operations having been implemented and effective since 1985. Quality Control functions as the "inspection" arm of QA and is responsible for all inspection and test activities, NDE, special processes and calibrations.

Quality Assurance is the administrative entity of the QA department and as such is responsible for setting up, monitoring, maintaining and reporting on Academy's Quality system for compliance to ABSA, ISO-9001 and API Q1 quality system requirements. The Quality Department is responsible for controlling product and processes from receipt of an order to delivery of product to ensure compliance to applicable API product specifications and Quality system requirements under ABSA, ISO-9001 and API Q1 quality system specifications.